JUNKER JUMAT 6S 18-20S-18 – Year 2017

Grinding CNC Cylindrical OD Grinder Machine

Space needed:approx. 4700x3650x3000 mm

with CNC control

make SIEMENS

swing diameter 320 mm

clamping length 1.200 mm

max. workpiece weight 150 kg

JUNKER JUMAT 6S 18-20S-18 Catalogue Information :

JUMAT 6S 18-20-18 – extremely short grinding time, maximum quality

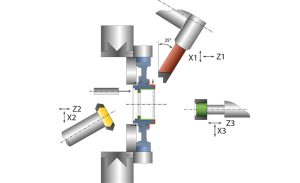

Simultaneous grinding with three grinding wheels – with a wheel as an example

Quality, cycle time, availability – anyone who knows grinding technology, knows what the JUMAT series represents. With its various sizes and numerous grinding spindle versions it offers an unsurpassed level of versatility.

With the new JUMAT 6S 18-20-18, the engineers at JUNKER have once again managed to extend their current portfolio. The new machine guarantees maximum quality through complete grinding in a single clamping set-up with an extremely short grinding time, thanks to the simultaneous use of three grinding wheels. All wheelheads feature a separate X and Z axis which enables workpieces to be ground simultaneously with all three grinding wheels. One grinding spindle ensures precise taper and plane surfaces (Z/X1), another takes care of the shoulder (Z/X2), while the last spindle grinds the internal diameter and shoulder (Z/X3). Further advantages include the redevelopment of the gearwheel grinding, which is based on the use of a perfect workpiece support. This is achieved through the center clamp, consisting of hydrostatic bearing and precision power chuck. This enables the workpiece to be ground simultaneously and on both sides.

The JUMAT 6S 18-20-18 shows the optimization potential that lies behind every little detail in the manufacture of precision technology. Whether it be grinding tool costs, which are kept down through long tool service lives or tailor-made solutions to meet customer requests – JUNKER has been making things possible for decades.