Citizen L32XII LFV CNC Sliding Headstock Type Automatic Swiss Lathe with LFV Technology – Year 2023

CNC Swiss, 7 Axis, HP cool, CAV32-LE-IS barfeed, New 2023

Specifications:

Spindle hole dia. 1.26″

RPM 12,000 RPM

Power 3 hp

Axis # 7

Equipped With:

CAV32-LE-IS barfeed, s/n V37502, 2023

Live Tooling

Sub-Spindle

Cool Blaster Mist Control

HP Coolant

34 ATC including 12+1 B-Axis Holder

JBS-15T Tool Holder

| Item | Citizen L32 VIII | Citizen L32 IX | Citizen L32 X | Citizen L32 XII | |

|---|---|---|---|---|---|

| Maximum machining diameter | 32mm Dia. | ||||

| Maximum machining length | GB machine | 320mm/chuck | |||

| GBL machine | Workpiece diameterx2.5/chuck | ||||

| Maximum drilling diameter for main spindle | 12mm Dia. | ||||

| Maximum tapping diameter for main spindle(tap, die) | M12(Cut tap) | ||||

| Spindle through-hole diameter | 39mm Dia. | ||||

| Spindle speed | Max.8,000min-1 | ||||

| Maximum chuck diameter of back spindle | 32mm Dia. | ||||

| Maximum drilling diameter in back machining process | 10mm Dia. | ||||

| Maximum tapping diameter in back machining process | M10(Cut tap) | ||||

| Back spindle speed | Max.8,000min-1 | ||||

| Maximum drilling diameter for gang rotary tool | 8mm Dia. | ||||

| Maximum tapping diameter for gang rotary tool | M6(Cut tap) | ||||

| Gang rotary tool spindle speed | Max.6,000min-1 | ||||

| Maximum drilling diameter for rotary tool of the opposed tool post Note) Optional feature to all types |

8mm Dia. | ||||

| Maximum tapping diameter for rotary tool of the opposed tool post Note) Optional feature to all types |

M6(Cut tap) | ||||

| Rotary tool spindle speed of the opposed tool post Note) Optional feature to all types |

Max.6,000min-1 | ||||

| Maximum drilling diameter for back tool post rotary tool | OP | 8mm Dia. | |||

| Maximum tapping diameter for back tool post rotary tool | OP | M6(Cut tap) | |||

| Rotary tool spindle speed of back tool post | OP | Max.6,000min-1 | |||

| Number of tools to be mounted | Max.30 | Max.36 | Max.44 | Max.40 | |

| Tool size | Turning tool | 16mm Sq. | |||

| Rapid feed rate | X1 axis | 32m/min | |||

| X2 axis | 32m/min | ||||

| Y1 axis | 32m/min | ||||

| Y2 axis | – | 24m/min | |||

| Z1 axis | 32m/min | ||||

| Z2 axis | 32m/min | ||||

| Motors | For spindle drive | 3.7/7.5kW | |||

| For tool spindle drive(gang rotary tool post) | 1.0kW | ||||

| For back spindle drive | 2.2/3.7kW | ||||

| For spindle drive of opposed tool post | 1.0kW Note) Optional feature to all types | ||||

| For spindle drive of back tool post | OP | 1.0kW | |||

| For cutting coolant oil | 0.25kW | ||||

| Rated power consumption | 13.2kVA | ||||

| Load operation average power | 6.9kVA | ||||

| Center height | 1,050mm | ||||

| Weight | 2,900kg | ||||

| ATC device | L32XII ATC |

|---|---|

| Max. ATC tooling rotations | 12,000min-1 |

| Motor output | 2.2kW |

| Tool holder type | JBS-15T |

| No. of B-axis tools | 13 |

| Number of tools mountable on main unit | Max.34 |

| Tool changing time (chip to chip) | 4.0 sec |

| Maximum outer diameter of tools | 30mm Dia. |

| Maximum grip diameter | 10mm Dia. (ER16) |

LFV technology

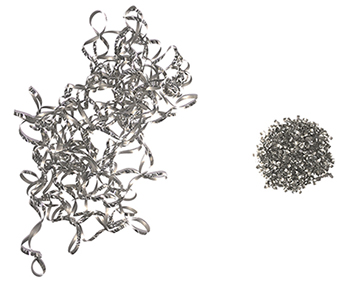

LFV technology is a unique Citizen control technology which breaks up the chips by vibrating the servo axis in the cutting direction and providing “air-cutting” time where the tool does not touch the material. As a result, this achieves solutions to various issues regarding chips, which has been a challenge for many years in the cutting process, such as improvements in the efficiency of small-diameter, deep-hole machining and fine cutting of chips produced when working with difficult-to-cut materials where the resulting chips have tended to be quite long. In addition, this technology achieves machining with high precision for an extended period of time by dramatically reducing the chip volume and preventing defects on the workpiece surface.

Differences in the shape of chips with the same weight

(material: SUS304)

Left: chips from conventional cutting

Right: chips from LFV technology

- LFV is a registered trademark of Citizen Watch Co., Ltd.