04/01/2026

By

CNCBUL UK EDITOR

Off

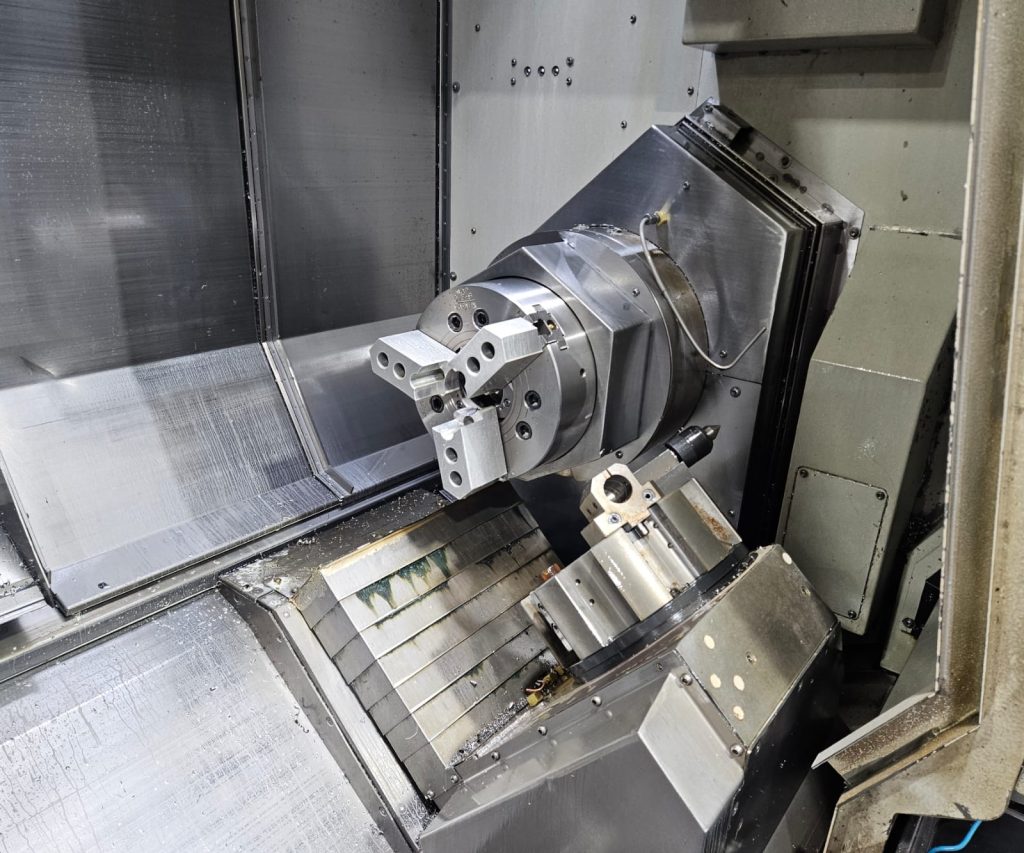

MAZAK INTEGREX 300-IVST CNC MultiTasking Turn-Mill Center – Year 2009 For Sale

| Machine Identification | |

|---|---|

| Machine Type | CNC Multi-Tasking Machine |

| Model | INTEGREX INT-300 IV ST |

| Control System | MAZATROL MATRIX Control |

| Country of Origin | Japan |

| Machining Capacity | |

| Max Swing Over Bed | Ø 850 mm |

| Max Machining Diameter (Upper / Lower Turret) | Ø 760 mm / Ø 420 mm |

| Max Machining Length | 1524 mm |

| Axis Travels | |

| X-axis Travel (Upper Turret) | 630 mm |

| X2-axis Travel (Lower Turret) | 230 mm |

| Y-axis Travel | 230 mm |

| Z-axis Travel (Upper Turret) | 1585 mm |

| Z2-axis Travel (Lower Turret) | 1530 mm |

| B-axis Travel | 225° |

| C-axis Travel | 360° |

| Spindle Specifications | |

| Main Spindle Speed | 4000 rpm |

| Main Spindle Nose / Bore | A2-6 / Ø 88 mm |

| Main Spindle Bearing ID | Ø 130 mm |

| Main Spindle Indexing Increment | 0.0001° |

| Second Spindle Speed | 4000 rpm |

| Second Spindle Indexing Increment | 0.001° |

| Second Headstock Stroke | 1530 mm |

| Second Headstock Rapid Traverse | 30,000 mm/min |

| Chuck Size (1st & 2nd Spindle) | 10 inch |

| 1st Spindle Bore Diameter | Ø 88 mm (3.46″) |

| Feed Rates | |

| Rapid Traverse X / X2 / Z / Z2 | 38,000 mm/min |

| Rapid Traverse Y-axis | 26,000 mm/min |

| Rapid Traverse C-axis | 400 rpm |

| Jog Feed Rate (All Axes) | 2000 mm/min |

| Motor Power | |

| Main Spindle Motor | AC 26 kW / AC 30 kW (40 HP) |

| Second Spindle Motor | AC 26 kW / AC 22 kW (35 HP) |

| Milling Spindle Motor | 18.5 kW |

| Coolant Pump Motor | 1.2 kW (Lower Turret: 0.18 kW) |

| Tooling & Turrets | |

| Lower Turret | 9-position Drum Turret |

| Rotary Tool Spindle Speed | 12,000 rpm |

| Tool Magazine | 20 CAPTO / 20 KM / 20 MAS |

| Optional Tool Magazine | 80 KM Tool Magazine |

| Control & CNC Functions | |

| EIA/ISO Simultaneous Control | 5-Axis |

| Tool Tip Point Control | Simultaneous 5-Axis |

| Shape Compensation | Rotary Axes / MAZACC-2D |

| Cylindrical & Polar Coordinate | G07 / G12 / G122 |

| Thread Cutting Function | Available |

| Automatic Tool Length Measurement | G37 |

| User Macro Variables | 600 Pairs |

| Additional Workpiece Coordinate Systems | 300 Pairs |

| Inverse Time Feed | Available |

| Standard Equipment | |

| Complete Coolant System | Included |

| Chip & Coolant Guard | Full Coverage |

| Active Vibration Control | Included |

| Intelligent Thermal Shield | Included |

| Intelligent Safety Shield | Included |

| Mazak Voice Adviser | Included |

| Virtual Machining | Included |

| 15″ Color LCD | Included |

| Optional Accessories | |

| Renishaw Probe | OMP-40 (for parts) |

| Chip Conveyor | Side Disposal, Hinge Type, 1500U |

| Through Coolant | Up to 15 kg (Upper Turret) |

| Tool Eye | Automatic |

| Signal Tower | 3-Color Light |

| Overload Detection System | Included |

| Hard & Soft Jaws | One Set Each |

| Physical Data | |

| Machine Weight | 13,600 kg |