AXIS STROKES

| U0 AXIS (feeder) |

mm |

8,500 |

| X0 AXIS (longitudinal) |

mm |

200 |

| Y0 AXIS (transversal) |

mm |

975 |

| Z0 AXIS (vertical) |

mm |

470 |

| A0 AXIS (electrospindle rotation) |

° |

-120° ÷ +120° |

| V0 AXIS (transversal) |

mm |

210 |

| W0 AXIS (vertical) |

mm |

95 |

POSITIONING SPEED

| U0 AXIS (feeder) |

m/min |

0 ÷ 85 |

| X0 AXIS (longitudinal) |

m/min |

56 |

| Y0 AXIS (transversal) |

m/min |

22 |

| Z0 AXIS (vertical) |

m/min |

22 |

| W0 AXIS (vertical) |

m/min |

25 |

| V0 AXIS (transversal) |

m/min |

25 |

LOADING UNIT – PROFILE POSITIONING

| Loading feeder with adjustable gripper |

|

● |

| Max. loadable profile length |

mm |

7,500 |

| Belt loading magazine |

|

● |

| Profiles loadable into the magazine |

pcs |

9 |

| Theoretical minimum cutting length |

mm |

0 |

| Electronic axis gripper positioning (V and W axes) |

|

○ |

| Max. loadable profile width |

mm |

200 |

| Minimum profile section without counterblocks |

mm |

30 × 30 |

MILLING UNIT

| Maximum power in S1 |

kW |

8.5 |

| Toolholder cone |

|

HSK-63F |

| Maximum speed |

rpm |

24,000 |

| Cooling through heat exchanger |

|

● |

| Minimal oil diffusion lubrication system |

|

● |

| Automatic tool rotation |

° |

-120° ÷ +120° |

LOWER MILLING UNIT (OPTIONAL)

| Maximum power in S1 |

kW |

2.0 |

| Maximum speed |

rpm |

24,000 |

| Toolholder |

|

ER25 |

| Electrospindle controlled on 3 axes with simultaneous interpolation |

|

● |

| Machinable section in Y |

mm |

200 |

90° CUTTING UNIT

| Widia blade |

|

● |

| Brushless blade motor power |

kW |

2.5 |

| Blade diameter / thickness for 90° cutting unit |

mm |

250 / 1.9 – 400 / 3.8 |

| CN blade feed |

|

● |

| Minimal oil diffusion lubrication system |

|

● |

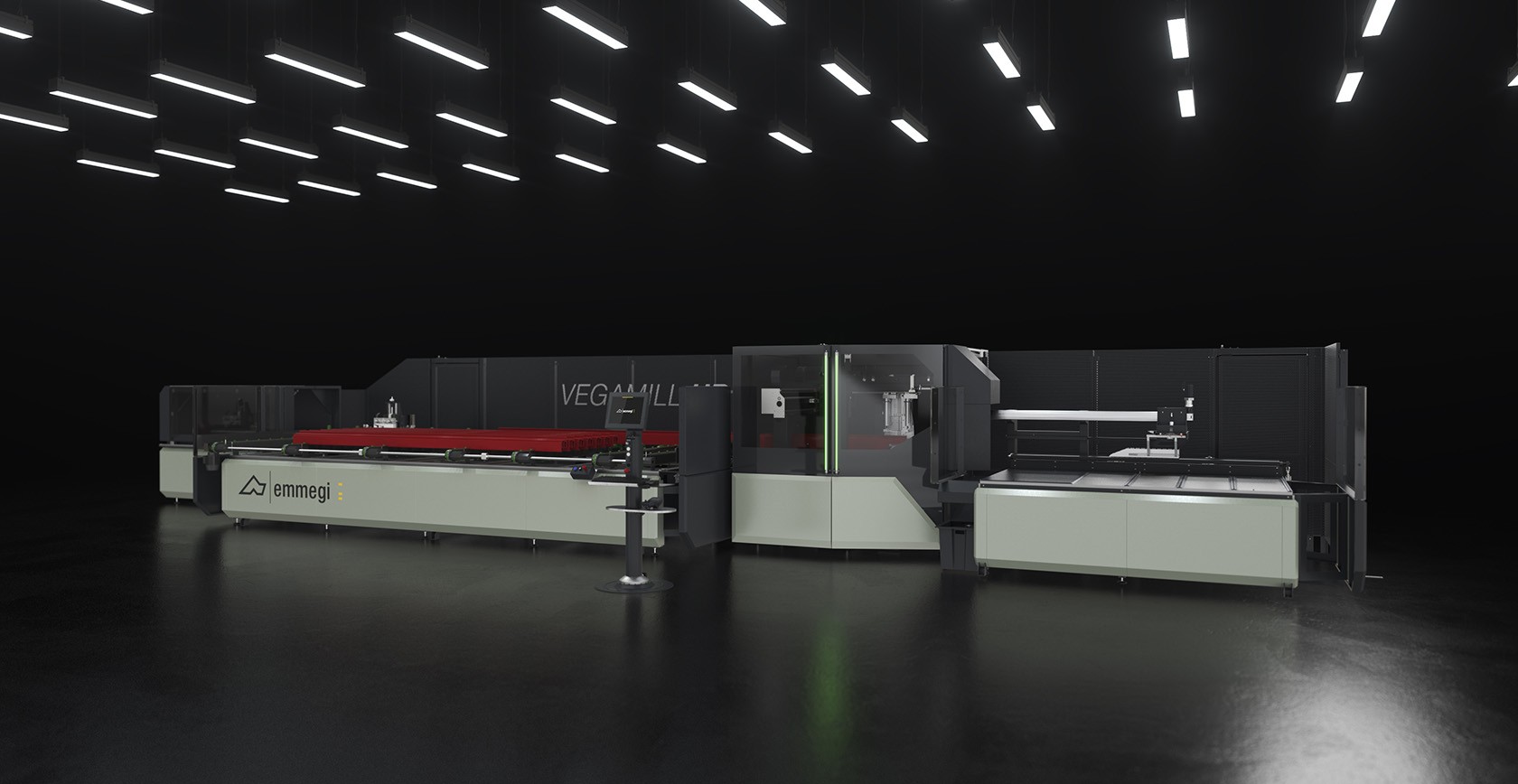

VEGAMILL – CNC Machining and Cutting-Off Centre

The

VEGAMILL is an

8- to 14-axis CNC machining and cutting-off centre,

designed for high-precision

cutting, drilling, and milling of

aluminium and light alloy profiles.

The machine consists of

four main operating units, engineered to deliver

flexibility, accuracy, and productivity in industrial profile processing.

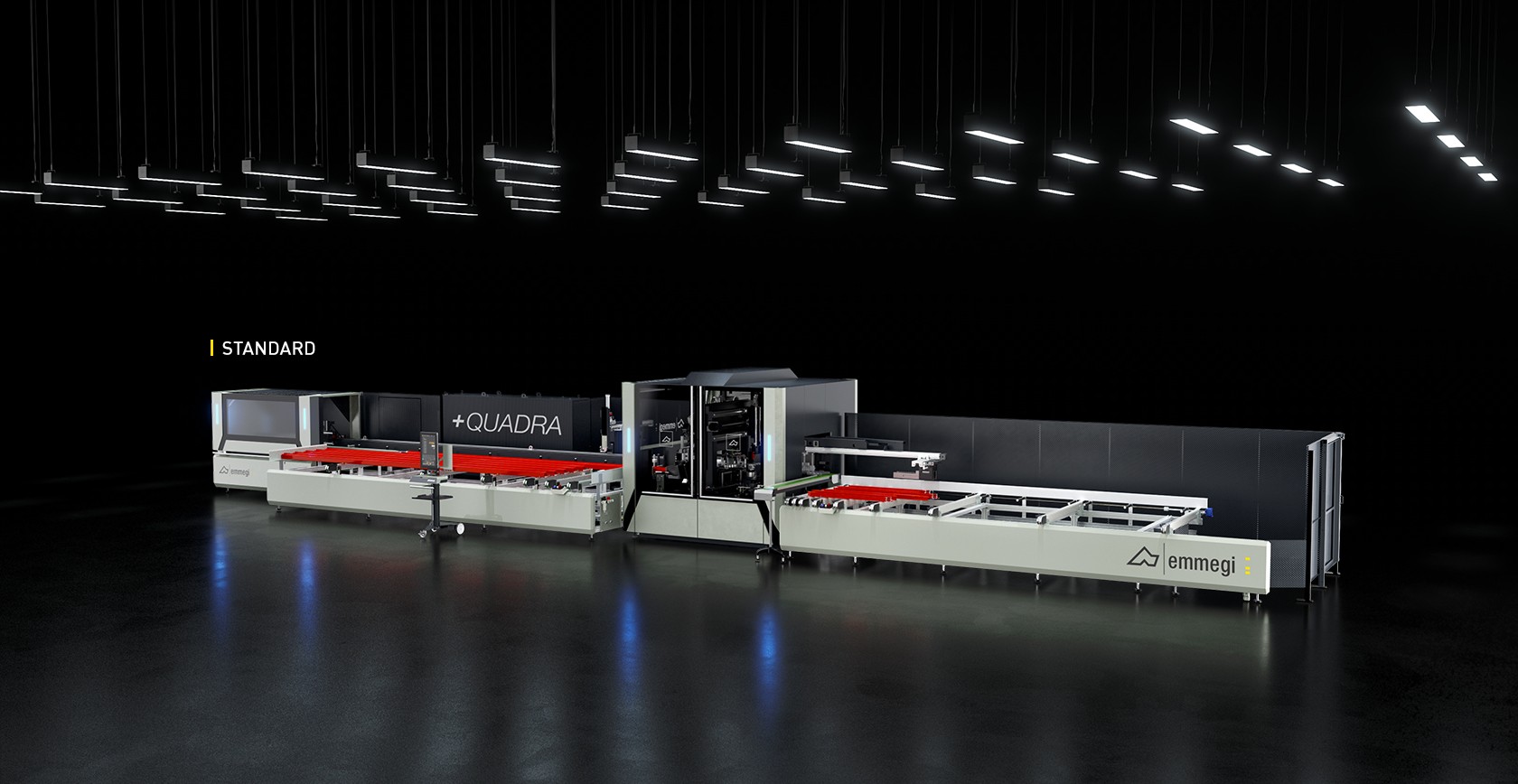

Loading and Feeding System

The system includes an

automatic belt loading magazine for profiles with a

maximum length of

7,500 mm.

A

high-precision, high-speed push-feed system equipped with a gripper

picks up the profile and conveys it to the machining area.

The horizontal and vertical adjustment of the gripper is

manual as standard,

and can be

optionally automated by means of an

electronic positioning system on two controlled axes.

Machining Units

A

4-axis CNC milling unit, integrating both drilling and milling functions,

performs machining on the

upper and lateral faces of the profile.

An

optional 3-axis CNC unit is available for machining the

lower face of the profile.

Cutting Unit

The cutting unit, equipped with

250 mm and 400 mm blades,

performs accurate

90° cutting operations.

In the version equipped with a

600 mm blade, the unit is capable of performing

cuts with an inclination of up to

22°30\' to both the right and left.

These operations are carried out with high precision and efficiency thanks to a

brushless motor operating on a

CNC-controlled rotation axis

with an

absolute magnetic band.

Unloading System

The unloading unit can be configured in two alternative solutions:

- A conveyor belt, ideal for short components such as

brackets and hinges

- An unloading table equipped with an

automatic extractor and an

automatic tilting and translation system

Safety and Compact Design

All units forming the

VEGAMILL are protected by integrated safety guards,

eliminating the need for additional external enclosure guards.

This design ensures

compactness, flexibility, and ease of integration

within production environments.