Ensure Peak Performance of CNC Machines with Proactive Maintenance

The world of manufacturing has changed. Today, precision, speed, and efficiency are everything. It is not humanly possible to handle the complexities involved in this age’s manufacturing processes with the said attributes. This is where CNCs or Computer Numerical Control machines come in.

In a few words, CNCs are automated tools to manufacture things with the help of a computer program to ensure precision and efficiency. These have been around for some time now, and the results are terrific.

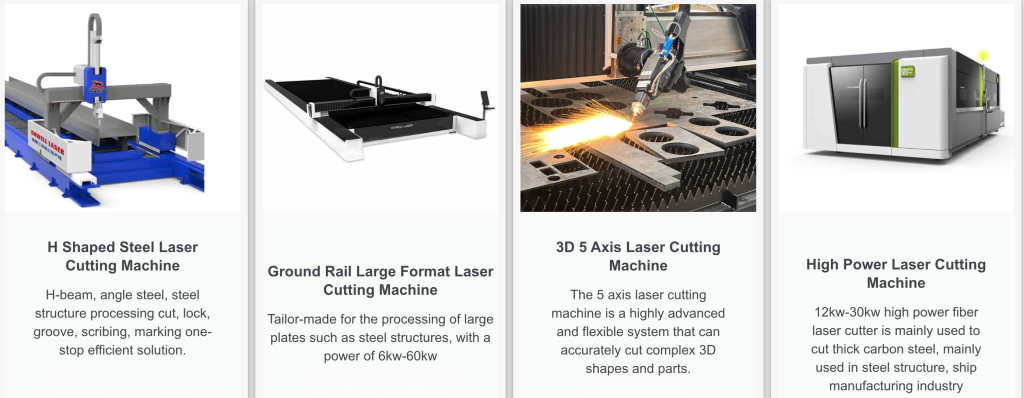

Still, some complain that they are losing earlier results. That’s because they fail to do the proper upkeep of their CNCs. The inevitable results are reduced lifespan, frequent issues, and prolonged downtimes. To avoid all of this, be proactive in maintaining your CNCs. Whether you have a simple CNC mill or something specific like a China fiber laser cutting machine for metal sheet manufacturers, follow a consistent maintenance schedule to keep them accurate and efficient.

Here’s a rudimentary blueprint you can follow.

Daily Maintenance Tasks

Yes, daily. You have to be consistent. Make sure these checks are performed before every shift starts. This is the first line of defense, which can save the CNC from a lot of problems down the line.

- Never allow debris to accumulate on the machine. Establish protocols to clear all kinds of residue before starting a new job. If this debris is allowed to accumulate, it can clog the drains or damage some parts. In the end, you get faulty measurements, and the whole purpose is defeated.

- The next important thing is to check all kinds of machine fluids. Lubrication fluids must not be too low, otherwise the critical components won’t function smoothly. Also, check the coolant. If it is low, the machine will overheat and break down.

- Never ignore sounds coming out of the CNC. If you hear any unusual ones like grinding or squealing, have it looked at the earliest. Sometimes, visual signs like fluid leaks are also found.

Weekly/Monthly Checks

Daily checks are done on the surface. You have to devise plans for in-depth check-ups of the CNC. This maintenance can be scheduled on a weekly or monthly basis. It will make sure you don’t have to deal with sudden breakdowns.

- Daily checks ensure the coolant is at the optimum level. But it also needs to be thoroughly cleaned of sludge or bacteria. Periodic maintenance will make sure there is no contamination and the filters are clean. This will allow a healthy flow.

- Spindles are the most important part of any CNC. They can get nicked or scratched with regular use. In such conditions, the tool won’t be handled properly, and a precise finish can’t be expected. In the same way, make sure the pull studs are free from wear and tear.

- Check the automatic lubrication system manually. Make sure that all lines are clear and every part of the machine is getting enough lubricant. Normally, you can check it visually. Tools are also available for more detailed inspection.

- If your CNC has belt-driven components, check their belts for signs of wear, tear, cracking, or fraying. Make sure the belts are not loose or too tight. They must be properly tensioned.

Advanced Optimization Tips

Your CNC will work fine with the above-mentioned basic maintenance tips. But, if you want to get the most out of it, ensure the following.

Analyze Vibrations of your CNC

Any change in a machine’s vibration signature can tell a lot about its state. You can use a vibration analyzer to detect even subtle changes. If there is a change in your CNC’s vibration signature, have it thoroughly looked at. There must be a faulty bearing or spindle, ready to fail.

Backlash

When there is a very small space left between a ball screw and nut, backlash can occur. This happens due to mechanical wear in the axes of the CNC machine. It can happen over time, and there is often no particular reason for it. Make sure you check for backlash regularly.

Ensure Proper Alignment of Spindles

This is especially important if your machine has multiple axes. If misaligned, it will lose precision and won’t produce accurate parts. Only with regular checks can you ensure that they are properly aligned.

Try Smart Maintenance

Just like everything else, CNC maintenance is also getting smart. It has a visible edge in effectiveness over traditional maintenance practices.

Smart maintenance uses sensors to collect data, analyze it, and then predict which part needs what and which one is most likely to fail. Specific sensors are placed on critical components like spindles and servo motors. They monitor continuously and provide data about temperature, vibration, etc. This data is then analyzed to detect anomalies. We can predict the failure of any component with some degree of accuracy in this way.

The prime advantage of smart maintenance is that maintenance can be scheduled proactively, downtime can be adjusted, and unwarranted breakdowns can be avoided.

Train your Operators

All of this is well and good. But you can’t do without a properly trained and experienced operator. Even the best-kept machine won’t work optimally in the hands of a green novice. Think of a trained operator as your first line of defense against CNC machine failure. He should be adept at his job and be able to perform the daily checks.

Keep Maintenance Records

It is good practice to keep records of all maintenance activities performed on the CNC machine. From daily checks to scheduled repairs, all should be listed. This will create a chronological history of repairs. It will help a lot if you experience some recurring problems.

A CNC machine is not just another tool. It requires a significant upfront investment. To protect that investment, you need to care for it with a proactive approach. Don’t wait for problems to arise. They would most likely have done enough damage by then. Prepare structured maintenance plans with daily, weekly, and monthly goals. Stick to them. Only by consistent maintenance can you ensure that your CNC machine remains an asset for your manufacturing operation.