Description

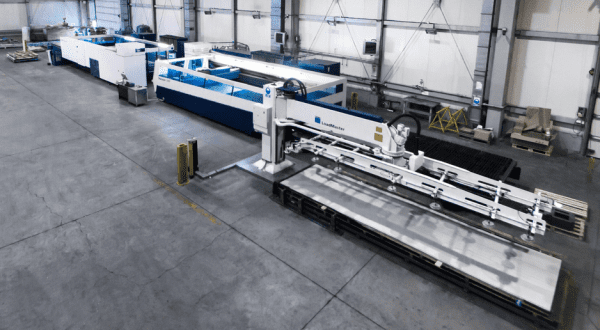

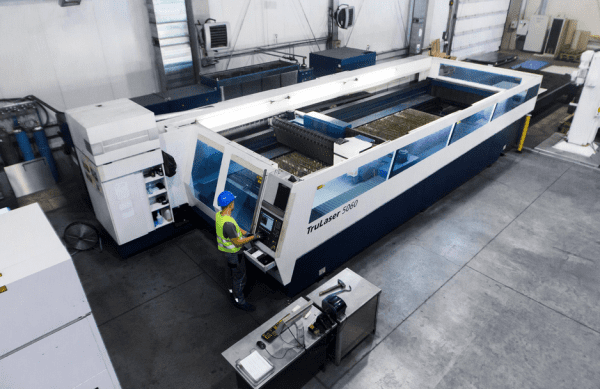

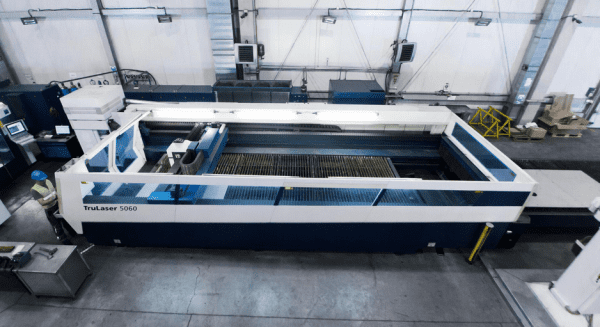

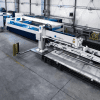

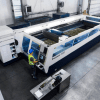

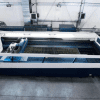

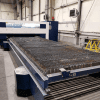

Trumpf TruLaser 5060 – Year 2012

CNC laser cutting machine

| Metal length | 6000 mm |

| Power | 7000 W |

| Metal width | 2000 mm |

| Option to cut tubes | no |

| Max thickness | 30 mm |

| CNC | yes |

| CNC type | SIEMENS SINUMERIK 840D |

| Travel X | 6000 mm |

| Travel Y | 2000 mm |

| Travel Z | 115 mm |

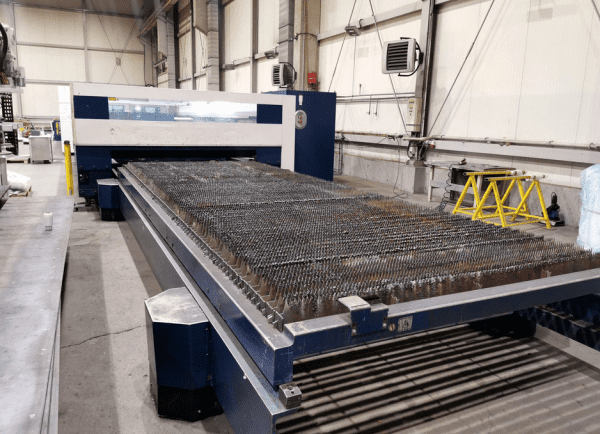

| Max weight of the workpiece | 4800 kg |

| Trumpf TruLaser 5060 | |

| Length x width x height | 16950.0 × 5550.0 × 2550.0 |

| Weight | 16000 kg |

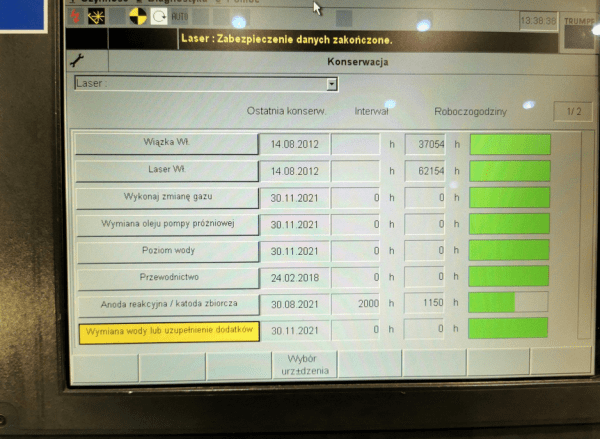

| Worked hours | 62154 hours |

Technical data of the TRUMPF TruLaser 5060 laser cutter

– laser power: 7000 W (7 kW)

– dimensions of the working table (length x width): 6000 x 2000 mm

– feeds in the X/Y/Z axes: 6000/2000/115 mm

– maximum detail thickness (structural steel): 30 mm

– maximum detail thickness (black steel): 25 mm

– maximum detail thickness (aluminum): 15 mm

– maximum sheet weight: 4800 kg

– positioning speed with simultaneous operation of the X and Y axis drives: 300 m / min

– positioning deviation: 0.05 mm

– beam on time: 37054 h

– laser on time: 62154 h

– compressed air connection: 7-10 bar

– nitrogen connection N2 : 30 bar

– O2 oxygen connection: 20 bar

– connection power: 130 kVA

– power supply: 400V; 50 Hz

– dimensions (length x width x height): 16950 x 5550 x 2550 mm

– total weight of the TruLaser 5060 machine: 16000 kg

Equipment of the TRUMPF TruLaser 5060 laser burner

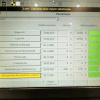

– CNC controller: SIEMENS SINUMERIK 840D

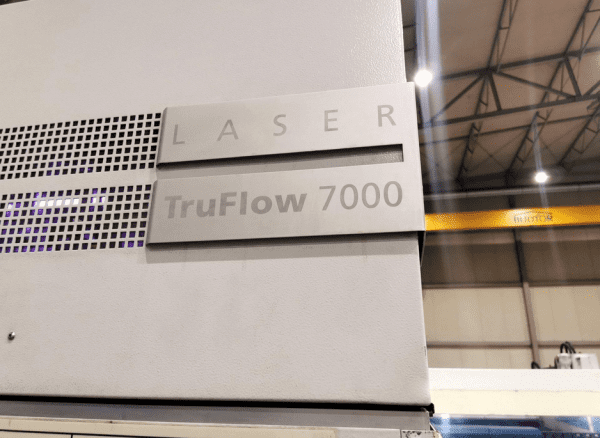

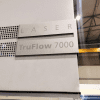

– laser source: TRUMPF TruFlow 7000

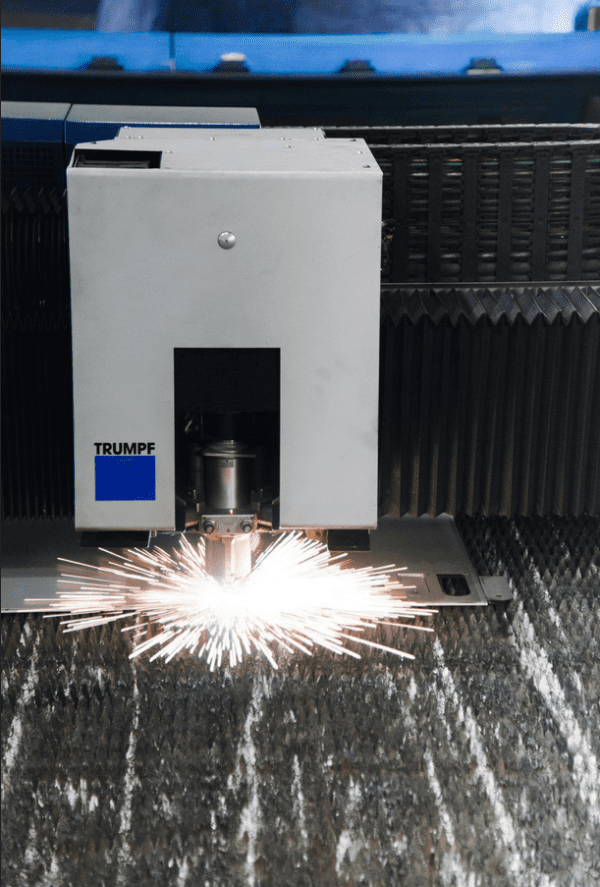

– cutting system: BrightLine

– cooling system: CoolLine

– system of one cutting head 250D50

– a computer with Windows XP

– USB connector

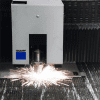

TRUMPF TruLaser 5060 7 kW laser was built in 2012. The machine used for laser cutting of sheet metal made of structural steel, black steel or aluminum is equipped with the latest technology to increase productivity and machining precision. The special BrightLine system makes the edges of thicker raw materials much smoother than in the case of standard cutting, while the CoolLine system is used for selective cooling of the workpiece during cutting, enabling new geometries and increasing process reliability.

The TRUMPF TruLaser 5060 L19 laser cutter uses the extremely reliable TRUMPF TruFlow 7000 source, which generates a 7 kW laser beam, with which sheet metal with a thickness of 30 mm (structural steel), 25 mm (black steel) or 15 mm (aluminum) is processed. The installed modern SIEMENS SINUMERIK 840D CNC controller with all the necessary functions significantly simplifies the work of the machine operator, giving him full control over the cutting process. The laser cutter was serviced on a regular basis during its use.