Description

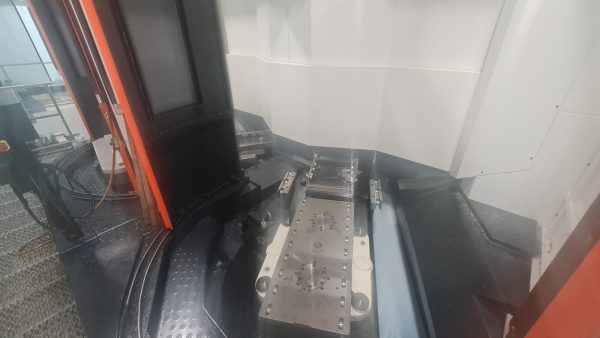

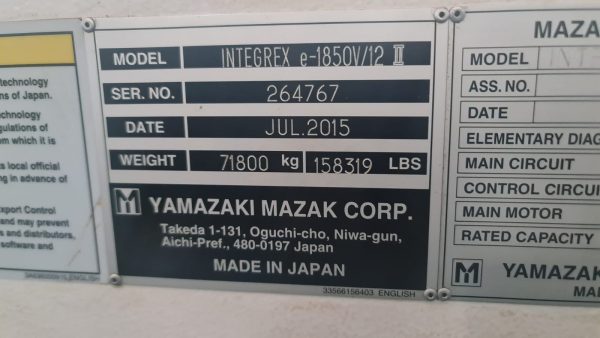

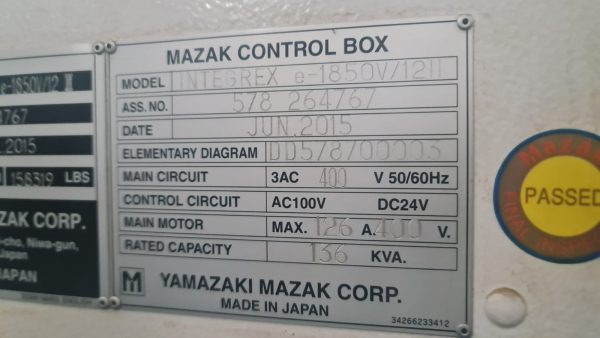

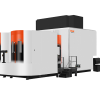

MAZAK INTEGREX e-1850V/12 II CNC MultiTasking Machine for sale

Manufacturer Catalogue Information about

MAZAK INTEGREX e-1850V/12 II CNC MultiTasking Machine:

INTEGREX e-1850V/12

PRODUCT: AUTOMATION/PALLETECH, INTEGREX

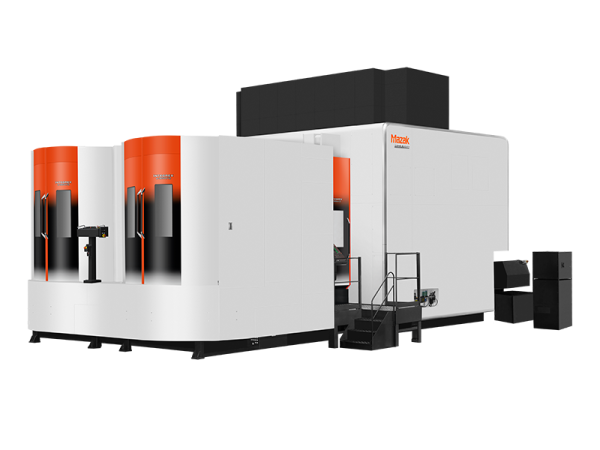

DONE IN ONE processing of large workpieces

Vertical multi-tasking machine

The INTEGREX e-1850V/12 II has a pallet size of up to 1850 mm diameter (option), a powerful, high accuracy main table that can turn large diameter work pieces and rapid traverse rate up to 40 m/min.

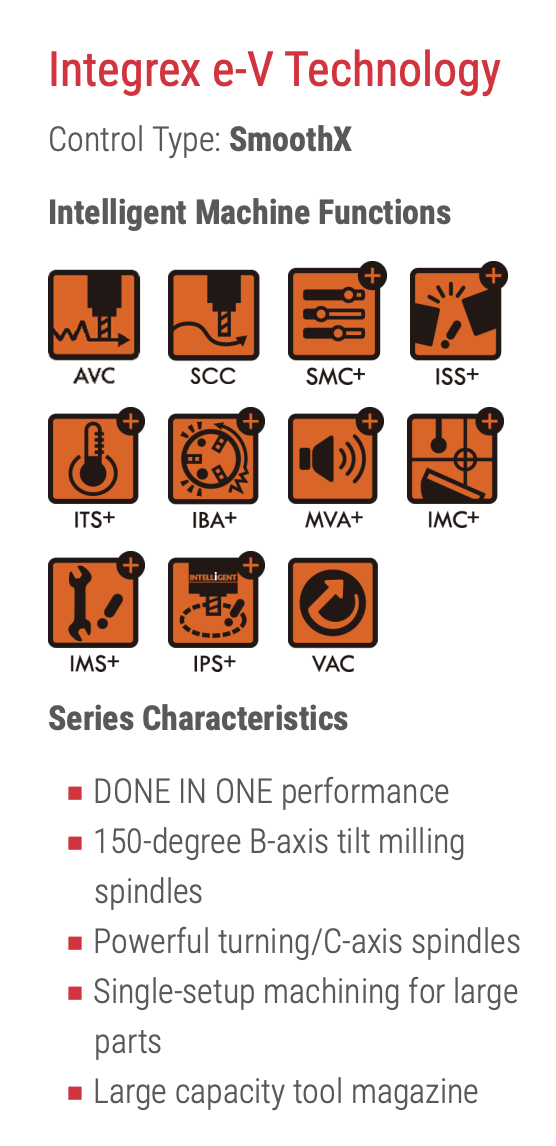

MAZAK INTEGREX e-V II series

Revolutionary multi-tasking machine – the complete fusion of machining center and CNC turning center

The milling spindle can tilt up to 150 degrees for both horizontal and vertical machining operations as well as angle boring and milling on multiple faces. In addition, the INTEGREX e-V II series have powerful, high accuracy main tables that can turn large diameter work pieces, and realize considerable reductions of machining time.

Machine Specifications

| Standard Machine | Values | |

|---|---|---|

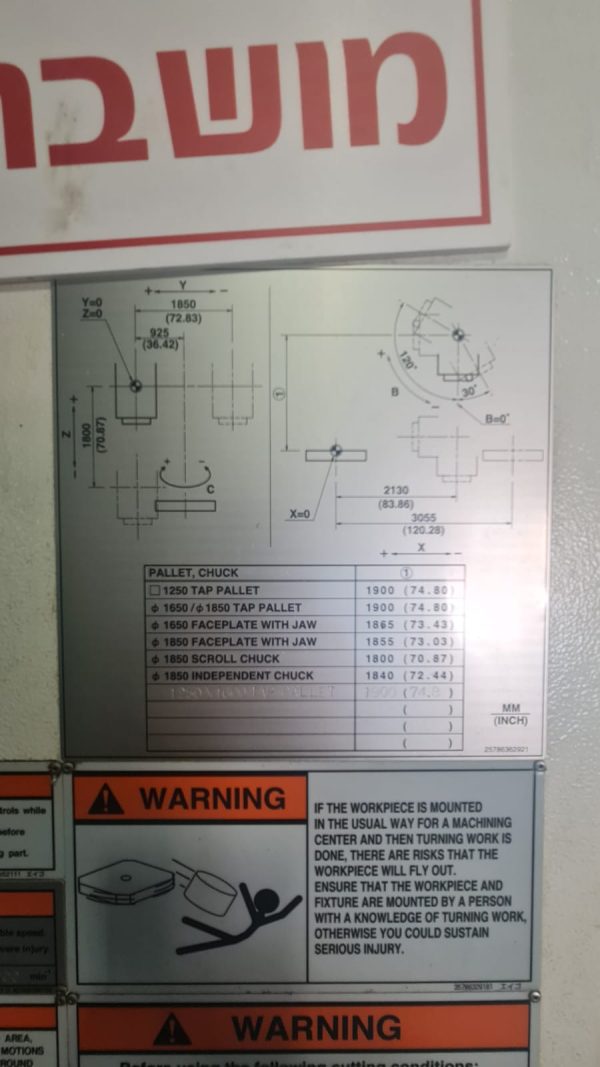

| CAPACITY | Maximum workpiece diameter | 2,350 mm |

| Maximum workpiece height | 1,800 mm | |

| X-axis stroke | 3,055 mm | |

| Y-axis stroke | 1,850 mm | |

| Z-axis stroke | 1,800 mm | |

| MILLING SPINDLE | Rotational speed max | 10,000 min-¹ |

| Power (30 minute rating) | 37.0 kg | |

| FEED RATES | Rapid traverse (X/Y/Z) | 40 m/min |

| TABLE (TURNING SPINDLE) | Rotational speed max | 250 min-¹ |

| Power (30 minute rating) | 45 kW | |

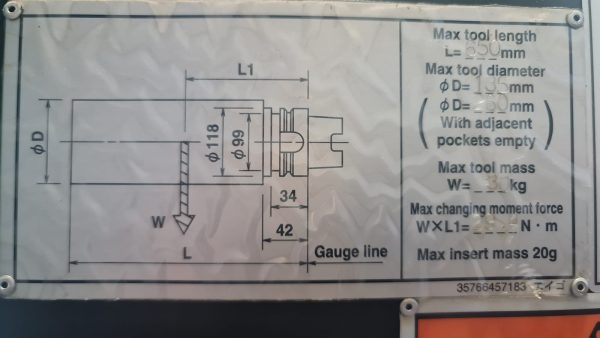

| ATC & TOOL MAGAZINE | Tool storage capacity (standard) | 40 |

| Tool storage capacity (option) | 80, 120, 160 | |

Standard equipment

FLOOD COOLANT SYSTEM WORK LIGHT

ONE SET OF MANUALS (CD) ONE SET OF MANUALS (PAPER) ACTIVE VIBRATION CONTROL INTELLIGENT THERMAL SHIELD INTELLIGENT SAFETY SHIELD MAZAK VOICE ADVISER VIRTUAL MACHINING

ONE SET OF ADJUSTING TOOLS

FOUNDATION KIT(LEVELING BLOCK)

THE SAFETY MEASURES ON WORLDWIDE LEVEL STANDARD TOOLING PACKAGE

Y AXIS TRAVEL 72.83″ (1850MM)

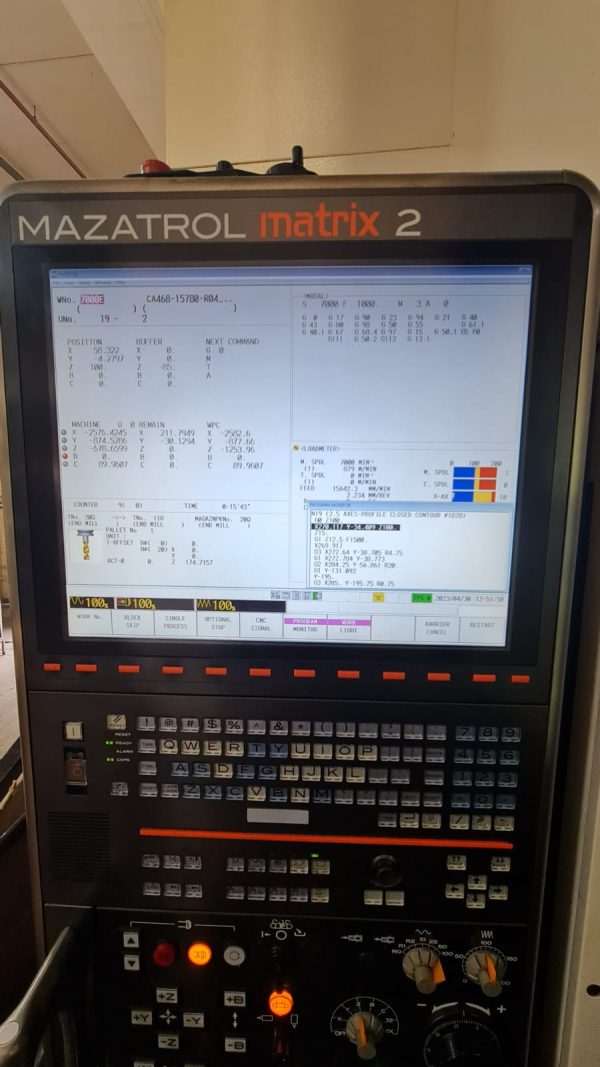

MAZATROL MATRIX 2 CONTROL

19″ COLOR LCD

E-TOWER

2 PALLET CHANGER

POWER TRANSFORMER

LATHE SPINDLE(TABLE)MOTOR AC45KW(60HP) LATHE SPINDLE(TABLE) SPEED 250 RPM

MILLING SPINDLE MOTOR AC37KW(50HP)

MILLING SPINDLE SPEED 10000 RPM

40 TOOL MAGAZINE

C-AXIS 0.0001 DEGREE INCR. (TABLE)

B-AXIS 0.0001 DEG/CNTRING (REQ. EIA/ISO) SPINDLE CHILLER UNIT

PREP. FOR MAZAK MONITORING SYS.-B RMP600 MAZA-CHECK

SCALE FEEDBACK SYSTEM (Z-AXIS)

ABSOLUTE POSITIONING SYS (LINEAR AXES) MANUAL PULSE GENERATOR 1 (DETACHABLE) SAFETY COVER FOR 2 PALLET CHANGER

POWER ROTATION OF 2PC LOADING STATION HYDRAULIC PRESSURE INTERLOCK

COOLERS FOR BALL SCREW (X,Y,Z-AXIS)

ROLLER GUIDES

AIR THROUGH MILL-SPINDLE SYS(SPNDL STOP) NIAGARA COOLANT (RECOMMENDED EQUIPMENT) OPERATOR DOOR INTERLOCK WITH LOCK-SWITCH AUTO POWER OFF(BREAKER TRIP)

ENCLOSED COOLANT & SPLASH COVER PREPARATION FOR CHIP CONVEYOR (SIDE)

USER MACRO (COMMON VARIABLES:600 PAIRS) MAZAK TAPPING/BORING TORNADO (EIA/ISO) EIA/ISO CODE INPUT FUNCTION (STANDARD) G37.AUTO TLM (LASER ROT.TOOL MEAS.REQ.)

ADD. EIA/ISO FUNCTIONS (REQ. EIA/ISO)

INVERSE TIME FEED

SEQUENCE NUMBER COMPARISON STOP FUNCTION TILTED WORKING PLANE

3-D COORDINATE CONVERSION

B)MAZACC-2D SOFTWARE(SHAPE COMPENSATION) ADD. WORKPIECE COORDINATE SYS. 300-PAIRS THREAD CUTTING FUNCTION

POLAR COORDINATES INPUT (EIA)

DIRECT ENTRY OF DRAWINGS DIMENSIONS

EIA PATTERN CYCLE (GRID, ARC)

CARDBUS I/F (2-SLOT)

LAN PORT

USB I/F

RELOCATION DETECTOR

Additional equipment – included in the package price

1250MM SQ.LOCATION BORE TAP PALLET(1 PCE 5-AXIS MACHINING PACKAGE

5-AXIS SPLINE INTERPOLATION (FOR PACK.B) 80 HSK-TOOL MAGAZINE

ADDITIONAL WORK LIGHT(HALOGEN LIGHT)

B)CYLINDRICAL & POLAR COORDINATE (EIA) B)MILL-SPINDLE SYNCHR. TAPPING(W/O TOOL) CHIP-CONVEYOR SIDE DISPOSAL (CONSEP) EIA DYNAMIC COMPENSATION 2 (INCLUDED 1) HI-PRESS MILL-COOLANT THRU(15KG(213PSI)) LARGE CHIP BUCKET (SWING TYPE)

LASER MILL TOOL MEASUR(NC4/FULL,W/O SOFT MAXIMUM PROGRAM SIZE : 8MB

OVERLOAD DETECTION SYSTEM

PROTOCOL B RS-232C

SCALE FEEDBACK SYSTEM FOR X,Y-AXIS SIGNAL TOWER (3 COLORS LIGHTS,SQUARE) TOOL BREAKAGE DETECTION (IN ATC AREA) TOOL EYE (AUTOMATIC)

TOUCH SENSOR (RMP600) RADIO TYPE F)TOOL RADIUS COMPENSATION / 5-AXIS HYDRAULIC UNIT TEMPERATURE CONTROL MILL TURNING (MAZATROL)

PREPARATION FOR FLASH TOOL SYSTEM INSTALLATION FEE

MODIFICATION TO LOADING STATION (FOR 1500*2000MM WORKPIECE)

This modification is specifically designed for rectangular workpiece with its size of 1500mm x 2000mm, there will be limitation on the direction to fix the workpiece

During C-axis rotation, stroke will be limited to <-75mm to -2980mm on X-axis>.

X-axis stroke will be decreased by 75mm to <0 to -2980mm>.