Description

JP Balancing Machine Joint Drive Balancing Machine PHW-50000H Mobile Balancer

| Technical data at a glance | PHW-20000 | PHW-30000 |

| Mass Scope of Workpiece(kg) | 20000 | 30000 |

| Max Diameter of Workpiece(mm) | Φ2800 | Φ3000 |

| Distance Between Two Support Bearings(mm) | Min 450 | Min 500 |

| Journal Diameter Scope of Workpiece(mm) | Φ60~400 | Φ80~500 |

| Max Distance between Driving Flange and Right Bearing Support (mm) | 5200 | 6000 |

| Rotational Speed of the Main Axis(r/min) | 195,336,561, 916,13744) |

127,218,365, 596,895,11044) |

| Motor Power (kw) | 551) | 751) |

| Torque of Universal Joint Shaft(N·m) | 5000 | 7800 |

| Length of Bed (mm) | 7000 | 8000 |

| Min Achievable Residual Unbalance Amount(emar) | ≤1g· mm/kg | ≤1g· mm/kg |

| Technical data at a glance | PHW-40000 | PHW-50000 | PHW-90000 |

| Mass Scope of Workpiece(kg) | 40000 | 50000 | 90000 |

| Max Diameter of Workpiece(mm) | Φ3400 | Φ3600 | Φ4200 |

| Distance Between Two Support Bearings(mm) | Min 500 | Min 500 | Min 800 |

| Journal Diameter Scope of Workpiece(mm) | Φ80~560 | Φ80~560 | Φ80~700 |

| Max Distance between Driving Flange and Right Bearing Support (mm) | 7000 | 8000 | 10000 |

| Rotational Speed of the Main Axis(r/min) | ≥120 | ≥120 | ≥120 |

| Motor Power (kw) | 901) | 1101) | 2201) |

| Torque of Universal Joint Shaft(N·m) | 9000 | 11000 | 15000 |

| Length of Bed (mm) | 9000 | 10000 | 12000 |

| Min Achievable Residual Unbalance Amount(emar) | ≤1g· mm/kg | ≤1g· mm/kg | ≤1g· mm/kg |

1) Frequency conversion

2) Can add to 75-180

3)Can add to 120~240

4)Stepless speed regulation

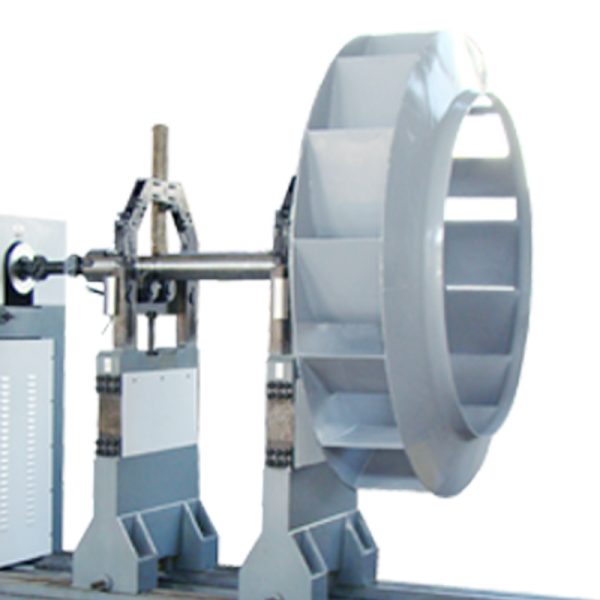

Universal Joint Drive Mobile Balancing Machine

Advantages:

1. Machine’s bed is integrate double guide rails achieved movable . 2. The reducer is added on the supporting pedestals and

lathe box,which keep both parts can move freely .

3. In order to protect the rollers and improve their uselife,

the equipment increase a hydraulic jacking machine to

facilitate the safe placement of the workpiece on the rollers. 4. Additional Add cylinders and hydraulic components to

the machine to achieve automatic locking of the safety

frame, reducing manpower and protecting safety 5. Machine adds an electric switch to brake,which is

convenientfor the operator to add/removing weight to

the product

6. Machine is equipped with an infrared marking device,

allowing the operator to find the angle easily and quickly 7. No special requirements for the foundation, just level it 8. The color of the equipment can be customized

Description:

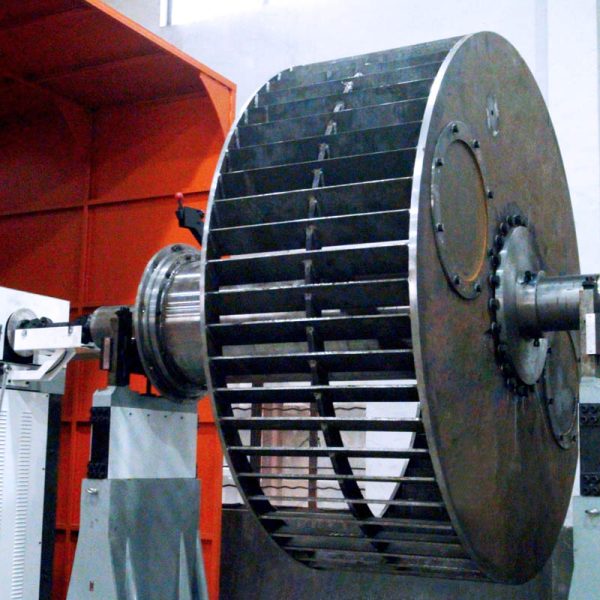

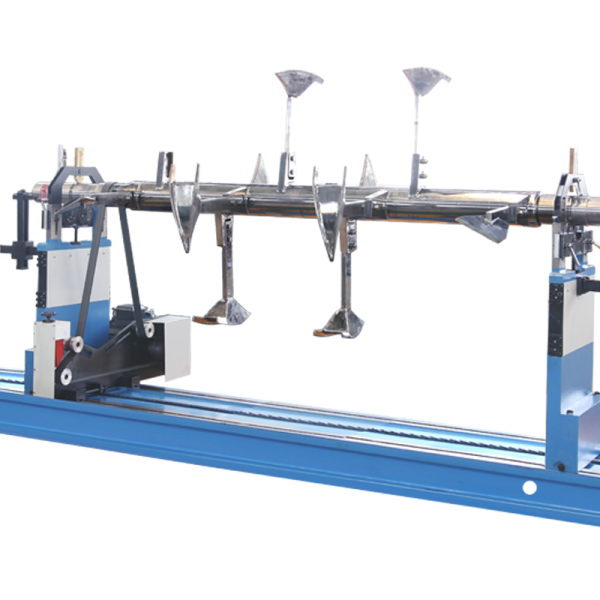

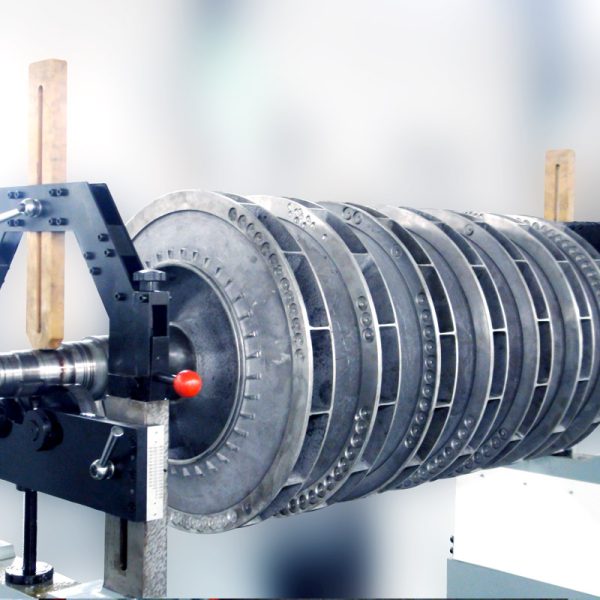

This balancing machine is mainly used in checking the balance of rotatable bodies such as good-sized motors, spindles of machine tools,blower, centrifuges, generator rotor , clinopodiums, pump impeller. drying cylinder. ceramic machinery,rollers,rubber sticks,etc.. Driven by gear box universal coupling , equipped with Variable speed motor to drive .Which ensures high quality balancing and precision. With wide speed range,large driving power, high precision and easy operation etc.

Machine Application

Ø Application range:

• This balancing machine is widely used in balancing rotatable bodies, such as kinds of Heavy sized

motors rotors, impeller, fans, centrifugal blowers, crankshaft, water pump, roller, etc ..

• Driven by universal joint , equipped with Variable speed motor to drive .Which ensures high

quality balancing and precision. quick booting ,easy operation. and high efficiency .

Machine Parameters

|

No. |

Specifications |

Parameters |

|

1 |

Maximum Weight of Workpiece(Kg) |

50000 |

|

2 |

Maximum Diameter of Workpiece(mm) |

φ 4000 |

|

3 |

Distance between two Bearing Pedestal(mm) |

700- 8000 (standard) |

|

4 |

Distance from coupling flange of drive shaft to center of farthest bearing(mm) |

8000 |

|

5 |

Journal Diameter of Roller Carriage(mm) |

φ65-600 |

|

6 |

Rotation speed when Diameter of Operating Transmission is 100mm (r/min) |

stepless regulation |

|

7 |

Motor Power (Kw) |

110(DC) |

|

8 |

Universal coupling torque(N·m) |

10000 |

|

9 |

Minimum Achievable Residual Unbalance(Emar) |

≤ 1 g.mm/Kg |

|

10 |

Unbalance Reduction Ratio(%) |

≥90% |

|

11 |

Power supply |

380 Voltage 3 Phase 50 HZ |

|

12 |

Machine Bed Length ( mm) |

10000mm |

The JP-580 computer control system:

FEATURES

1. 17-inch LCD screen

2. Windows 7 Operating System

A 3. Chinese,English, Russian&Spanish display

4. Limitless storage of rotor parameter

5. 10000 items storage of measuring records

6. Multi-methods of algorithms

7. 10-stage calibration offers higher precision 8. Multi-methods of Compensation

9. Cursor Guide function

10. add company name & logo on report.

TECHNICAL DATE:

B

1. Scope of RPM: 120-12000 r/min

2. Minimum resolution: 0.01mg

3. Shortest measuring time: 3s

4. Measurable dynamic range: 1:100000

DETAILS:

C

1. JP-580 Electrical Measuring unit is a system of top function and precision.

2. It can be applied in all kinds of single/double plate and hard/soft bearing machines, and can be connected with different velocity and pressure sensors easily.

3. The unit adopts industrial computer made in Advantech Co.

4. Featuring with high running speed and reliabilitystrong dustproof and shakeproof ability, it is applicable to various industrial environments.