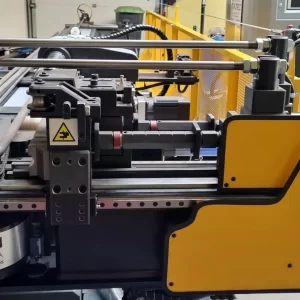

Description

HMT HORN Machine Tools 4L-STD Tube Bender – Year 2014

Capacity :6″

Left Hand Bend

*Tooling shown in photos included (Please see last picture for full list)

Reverse acting mandrel extraction system which increasese extraction force by 30% over conventional direct acting extraction. The cylinder has a 30” adjustable stroke so you can use mandrels with shanks of 12” to 15” lengths and long ball stacks for tight radius thin wall materials. Entire system is adjustable side to side with manual wheel crank and is also mounted on square rails with linear bearings. The mandrel rod rotates freely on bearings.

Manual and auto control modes.

Controller can store up to 99 bend programs.

Pressure die is direct acting and the pressure die pressure setting is easily programmed into the controller. There is a pressure gauge mounted on the pressure die cylinder for easy and quick reference. Directing acting pressure die is advantageous for absorbing any inconsistencies with the tube material and maintaining stable pressures throughout the bending process.

The pressure die assist is controlled by a dial on the side of the controller.

The clamp is toggle style and has a precision clamp feature. This feature allows the clamp to close until it reaches ¼” from fully closed. The operator can walk into the interference zone and perform final adjustment of the tube to align with the tooling and then press a button on the front of the bend arm to fully close the clamp. This is very useful if you need to locate the tube exactly on tangent and control the orientation.

Depending on wall thicknesses, the machine is capable of bending up to 6.0” with soft aluminum, up to 5.0” with annealed stainless steels, and up to 4.0” for Titanium and Inconel (material with very high strength and low elongation).

There is a heat exchanger to maintain consistent hydraulic oil temperature during warm days and/or heavy use.

The machine uses light curtains to monitor interference conditions in the bending zone. There is no pressure mat that can get dirty and fail rendering the machine unusable.

There is an auto lubricating system to ensure the slides are properly lubricated.