Description

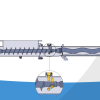

GEA gMaster CF 4000 – 3 Decanters – Year 2012

3 decanters for sale

Machine for separating juice into fractions from fruit pulp.

In working order.

Disassembled and stored in warehouse.

Good condition.

Replacement spare parts are available.

The development of the resource of machines is insignificant

Manufacturer Catalogue Information about GEA gMaster CF 4000 Decanters :

Well-being demands nothing but the best

The dedicated juice industry counts on most sensitive product handling and minimum product losses during the process.

Turning fruits and vegetables into premium juices – this objec- tive is at the heart and soul of each dedicated juice producer all over the world. Each process step has been carefully monitored so that the valuable product is not exposed to harm risks.

Careful product handling has been the tradition of juice producing industry for centuries. Along with it goes the maximum optimization of the individual process steps by using the most sophisticated machinery. Centrifugal separation plays a major role in this continuous optmization cycle. It enables processing of the trub in its freshest state and juicing of the fruits and vegetables immediately afterreceipt which helps a lot during production in high season. Centrifuges and decanters separate and clarify fast and efficiently with optimum yield.

Sophisticated technical details like the hydrosoft feed or the hydrohermetic sealing allow for the production of premium juice. Juicing fruits and vegetables by a decanter means getting high quality juices from the very start to the very end – top quality all over the process.

Centrifugal technology also helps juice producer to produce at very economical rates – making more juice, in less time, with less effort and investment. Centrifuges and decanters in the juice production – multipurpose technologies that pay off.

The advantages at a glance

• Minimized oxigene pick-up during extraction • Favourable influence on quality

• Production of clean, characteristic juice

• No impairment of taste

• Higher yield

• Better juice clarification

• Substantial extension of filter life and hence significant

savings of filter aid (layers and kieselguhr) • Savings in labour time

• Timely separation of the fining trub

(shortening of the fining time)

• Lower space requirement (storage capacity)

• Fast production of ready-to-sell single strength juices

A real boost to your profit

A healthy lifestyle is more of an issue than ever

these days. This explains in particular the success

of superfruits such as acai, goji berries, acerola, cowberries, cranberries and buckthorn berries as well as NFC juices. Juices from these fruits also display

a great deal of nutitional values due to their high proportion of antioxidents.

These innovative products have resulted in new requirements for the industry. Besides high yields, which are still an absolute priority, new features have gained importance such as easy cleanliness, cloesed process management for maximum

hygiene, processing with minimized oxidation and particularly rapid and yet simultaneously gentle juice extraction. GEA supplies customized processes and process lines for these and many other challenges.

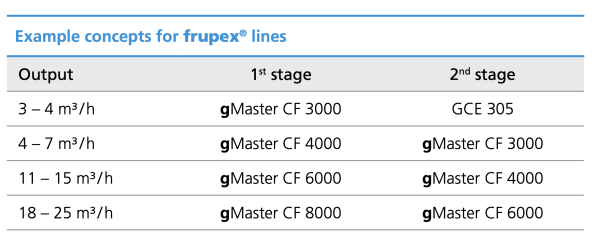

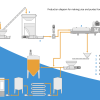

Centrifugal separation technology is still the key of cost-conscious production of high quality juice. It ensures optimum initial clarification before filtration, with minimal loss of juice. GEA centrifuges provide the right concept for every requirement, depending on whether a high yield or maximum throughputs are required. The GEA frupex® method shows how

it is possible to combine a gentle manufacturing process with maximum economy.

No limits to your business

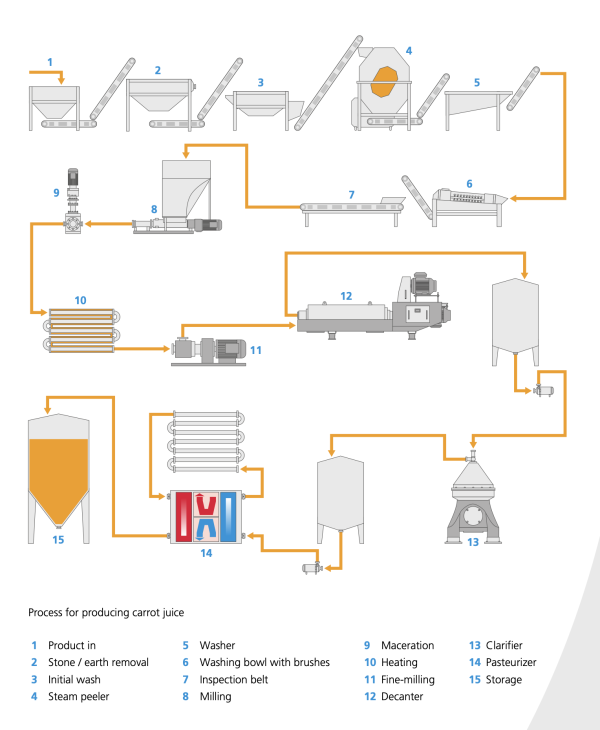

Nearly every fruit and vegetable can be processed:

• pome fruits

• berries

• stone fruits

• tropical fruits

• all kind of vegetable

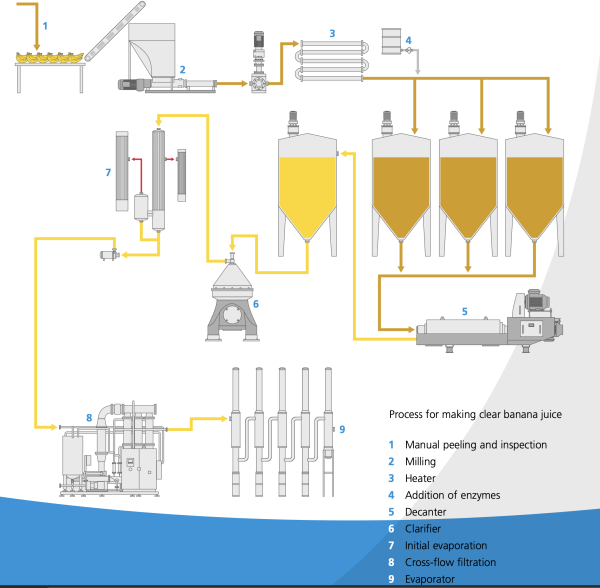

High quality juice from start to end with GEA Decanter

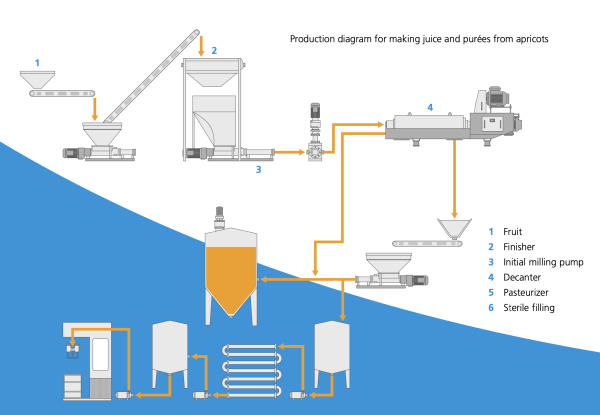

Pretreatment of the products before extraction

Extracting the juice

The first important process technology step in the production of apple juice is to mill the apples. Particle sizes from 5 to 8 mm diameter are the objective for presses, 3 to 5 mm for decanter use.

The following properties are required of a system to mill whole apples:

• Closed system to prevent oxigene pick-up. This

significantly reduces foaming and consumption of

ascorbic acid.

• Possibility to adapt the particle size with regards to the

ripeness and characteristics of the fruits. If the pieces of apple are too big, this will result in a lower yield; if they are too small, they will increase the colloid content of the juice and make phase separation more difficult.

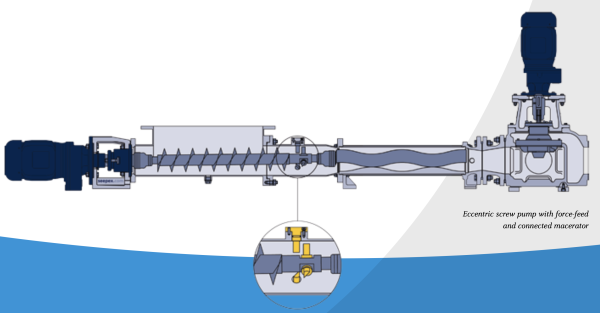

Milling Systems

Our milling system is best operated with a GEA eccentric screw pump that includes a pre-milling feature inside the pump. For further milling the fruits will be fed into a GEA

macerator which allows to adjust the particle size. This entire GEA system is closed to prevent oxigene pick-up.

A buffer tank is not needed: The pump is controlled by the level of the hopper which is installed above the eccentric screw pump.

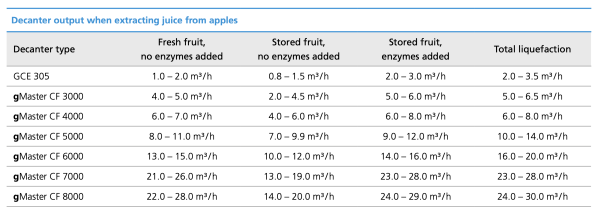

Following milling, further treatment of the mash depends on operational objectives. The variants below are found in the field:

• Direct juice extraction without any mash treatment,

usually to produce single strength juices.

• Addition of enzymes to the mash in the cold state • Addition of enzymes to the heated mash

(approx. 45 ̊C)

• Total liquefaction

In practice, these options are combined with addition of ascorbic acid to prevent browning.

roduction of grape juice

In principle, all varieties which have a relatively high acid content and produce aromatic juices are ideal for grape juice preparation. The selected produce should be healthy and ripe and have an appropriate must weight.

For production, the grapes should initially have their stemms removed. Beyond this, no further pretreatment of the grapes, such as additional pressing with rollers, for example, is required for juice extraction by means of decanters.

Adding enzymes to the mash of white grapes before phase separation can increase the yield and improve the degree of clarity of the juice produced even further. The juice then has the flavor removed, is subjected to an initial concentration process and the semiconcentrate is fined and clarified by ultrafiltration.

To prevent subsequent precipitation of tartrate, the contact method is used in conjunction with the GEA separation process. Following this tartrate stabilization process, the preconcentrated grape juice can be evaporated to the desired Brix content.

The process for the production of red grape juice is modified to extract the valuable phenolic compounds, namely colors and tannins, from the cells of the skins. For this purpose, with red grapes, for example, the mash is heated to 80 to 85 ̊C for 2 to 6 minutes and is then fed directly to the decanter without any time to stand. The hot juice is then vigorously exchanged with cold mash on the countercurrent principle and cooled down by a further cooling unit.

In the case of particularly pectin-rich varieties such as the Concord grape, for example (Hot Concord pro-cess), it is recommended that enzymes be added to the mash following heating and cooling but before it is passed to the decanter.

The following applications may arise for separators and decanters in conjunction with ultrafiltration

during the production of grape juice:

• Extracting juice from the grape mash

• Clarifying the freshly obtained juice

• Polishing the juice clarified and stabilized by means

of enzymes or by fining agents

• Clarifying the retentate in conjunction with

ultrafiltration

• Ultrafiltration

• Tartrate stabilization

The production of grape juice by decanter has both qualitative and economic benefits compared to the conventional process:

• Gentle method

• Better sensory quality

• No filtration auxiliaries required

For red grapes, there are additional benefits • Higher color yield

• Continuous process

• Simple cleaning

• Flexible and reliable

• Simple and space-saving