Description

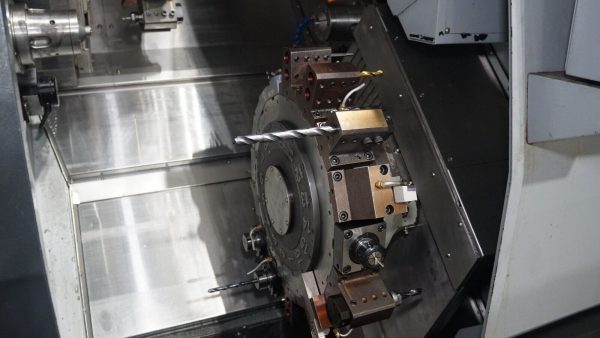

Ganesh Cyclone 52 TTMY – Year 2014

CNC Turning Center Twin-Spindle Twin-Turret

Machine Details

Twin-Spindle Twin-Turret with Simultaneous Machining

This machine is fast, versatile, precise and allows for single cycle execution of parts

Full “Y” Axis on Upper Turret

Full “C” Axis on Main and Sub Spindle

Dual 16 Stations Turrets, 32 Live Tools

Rugged BMT-65 Tool Holders

Powerful Mitsubishi M-720L CNC Control

6,000 RPM Integral Spindles (4,000 RPM Hi-Torque option)

Parts Catcher with Conveyor

Spindle Chiller Standard

51mm (2″) Bar Capacity

Features

double spindle

double turret

machining versatility

single set up

unique y axis design

simplified control

increased stability

horizontal jig assembly

individual component testing

laser testing

motion simulation

calibration

efficient chiller system avoids thermal deformation

integrated oil mist lubrication

no heating issues

low maintenance

main spindle – top turret

c axis machining

front machining

indexing to 0.001mm

sub spindle – bottom turret

back machining

indexing to 2-3 microns

thorough pre and post assembly testing

guaranteed cutting performance

Specifications

GANESH CYCLONE-52 TTMY DUAL SPINDLE CNC LATHE SPECIFICATIONS:

CAPACITY

Maximum turning diameter Inch 7.48″ (190 mm)

Maximum turning length Inch 15.75″ (400 mm)

SPINDLE

Spindle nose ASA Size A2-5

Spindle Bore Inch 2.40″ (61 mm)

Spindle Bar Capacity Inch 2.0″ (52 mm)

Chuck Size Inch 6″

Maximum spindle speed RPM 60-6,000 RPM (Integral Spindle) / 4,000 RPM Heavy Duty

Spindle motor horsepower 20-HP peak, 15-HP (30-minute duty rating)

SUB SPINDLE

Spindle nose ASA Size A2-5

Spindle Bore Inch 2.40″ (61 mm)

Spindle Bar Capacity Inch 2.0″ (52 mm)

Chuck Size Inch 6″

Spindle Center Height Inch 46.45″ (1,180mm)

Maximum spindle speed RPM 60-6,000 RPM (Integral Spindle)

Spindle motor horsepower 20-HP peak, 15-HP (30-minute duty rating)

LIVE TOOL TURRETS

Dual 16-Station Live Tool Turrets

Number of turret stations 16 x 2 32 (Any combination of 32 ID, OD or Live tool stations)

Turret index time (adjacent tool) Seconds 0.2 seconds

Turret index time (180-degree index) Seconds 1.2 seconds

Tool Size Inch 25mm (for square tool and round tool)

Collet Size Inch ER-32

Tool Holder Type & Size BMT65 Base Mount Tooling

Turret Thru-The-Tool-Coolant Optional 1,000 PSI High Pressure

“Y” AXIS

Y axis travel (Upper Turret only) Inch +/- 1.38″ (35mm)

Y axis Rapid Feed Rate Inch 236 Inch Per Minute (6m per minute)

“C” AXIS

Spindle Radial Resolution0.001^0360,000 radial positions + full contouring capability

RPM for Live Tools RPM 25 – 4,000 RPM

“B” AXIS (sub spindle)

B Axis Rapid Traverse Rate Inch1,573 Inch Per Minute (40m per minute)

B Axis Travel Inch 25.59″ (650mm)

AXIS SPECIFICATIONS

Axis Travel – X1, X2 – Axis Inch X1 5.94″ (150mm), X2 9.05″ (230 mm)

Axis Travel – Z1, Z2 – Axis Inch Z1 & Z2 17.32″ (440mm)

Rapid Travers Rate – X-axis ipm 630 ipm (16 m/minute)

Rapid Travers Rate – Z-axis ipm 1,573 ipm (40 m/minute)

Minimum Programmable Input Inch 0.000039″ (0.001mm)

Positioning Repeatability – X-Axis Inch 0.000050″ (0.012 mm)

Positioning Repeatability – Y-Axis Inch 0.000050″ (0.012 mm)

Positioning Repeatability – Z-Axis Inch 0.00010″ (0.002 mm)

Positioning Accuracy – X-Axis Inch 0.00020″ (0.004 mm)

Positioning Accuracy – Y-Axis Inch 0.00020″ (0.004 mm)

Positioning Accuracy – Z-Axis Inch 0.00040″ (0.008 mm)

FLUID CAPACITY

Hydraulic Tank Gallons 10.5 gallons (40 Liters)

Coolant Tank Gallons 70 gallons (280 Liters)

MACHINE WEIGHT Pounds 26,500lbs

MACHINE DIMENSIONS Inch Length 150″ / Width 105″/ Height 90″

A highly versatile twin-spindle twin-turret Machine perfectly suited for heavy duty complicated parts

8 axis, 32 live tools, Full “Y” Axis, 51mm bar

This includes an Orion unit cooler model TKS-2200V-HP-Q and a bar