Description

Davis Standard Winding Unwinding Automation Roll Handling Machine – Year 2019

| Year | 2019 |

|---|---|

| Make | Davis Standard |

| Model | Winder/Roll Changer |

| Davis Standard Winding Unwinding | Extruder |

| Width | 36″ Width (But Ran Wider Widths) |

|---|---|

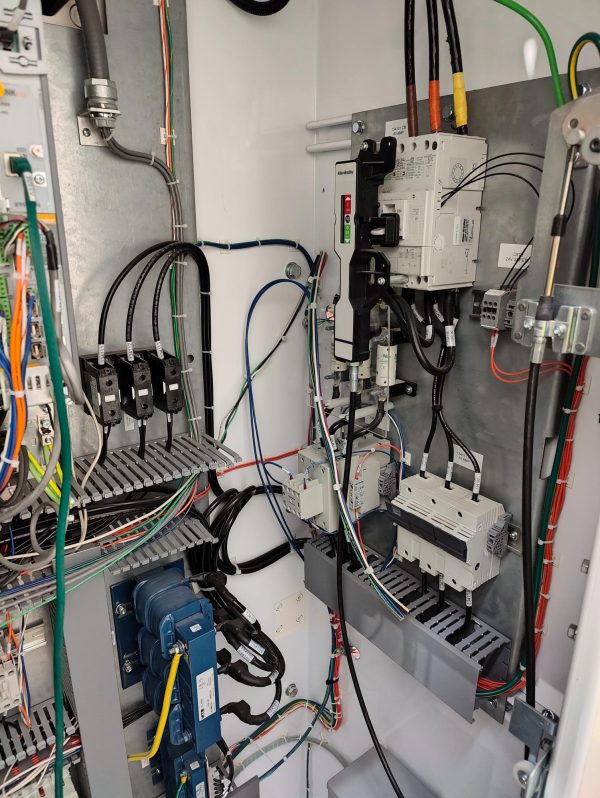

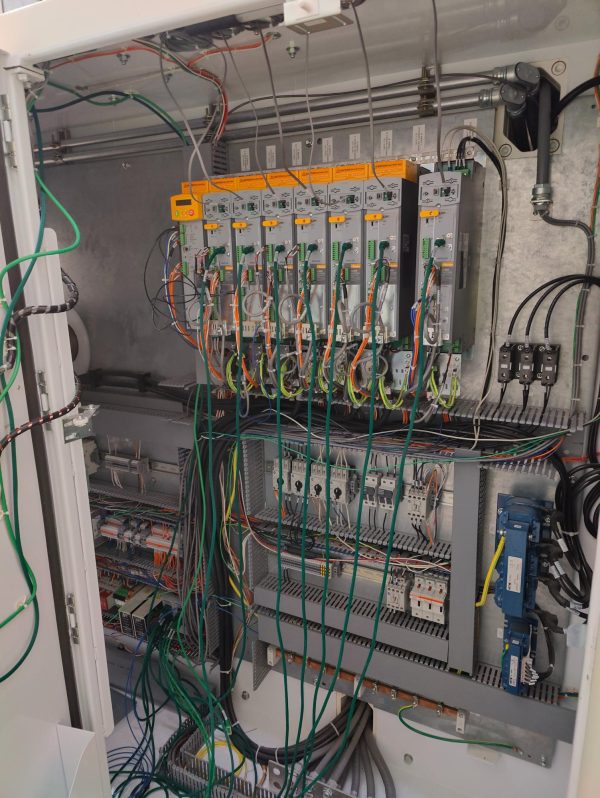

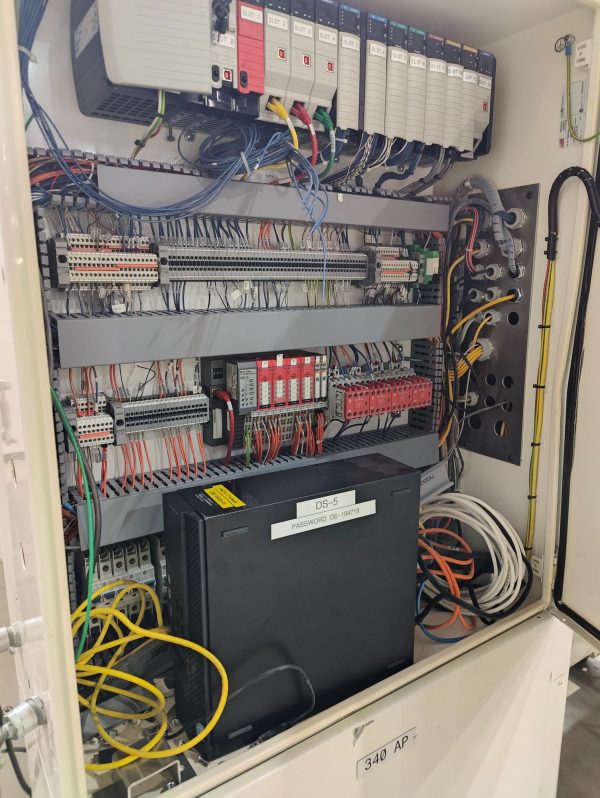

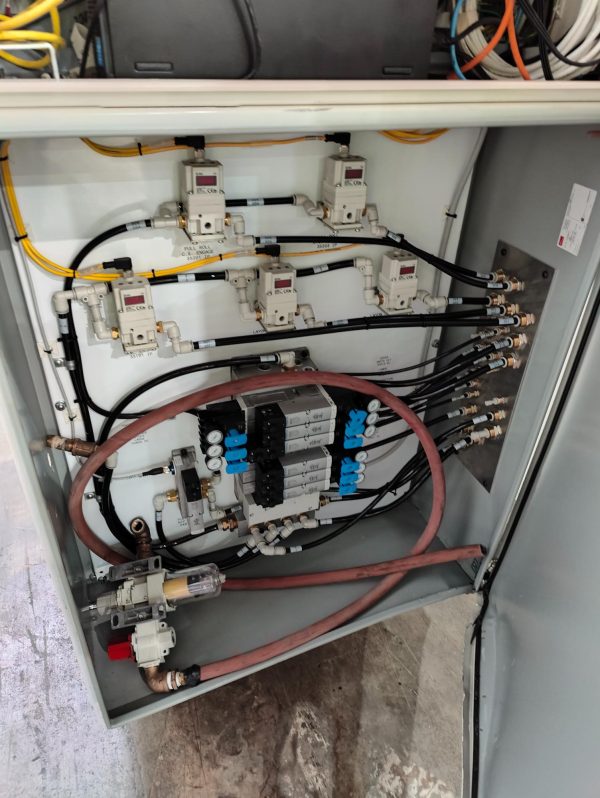

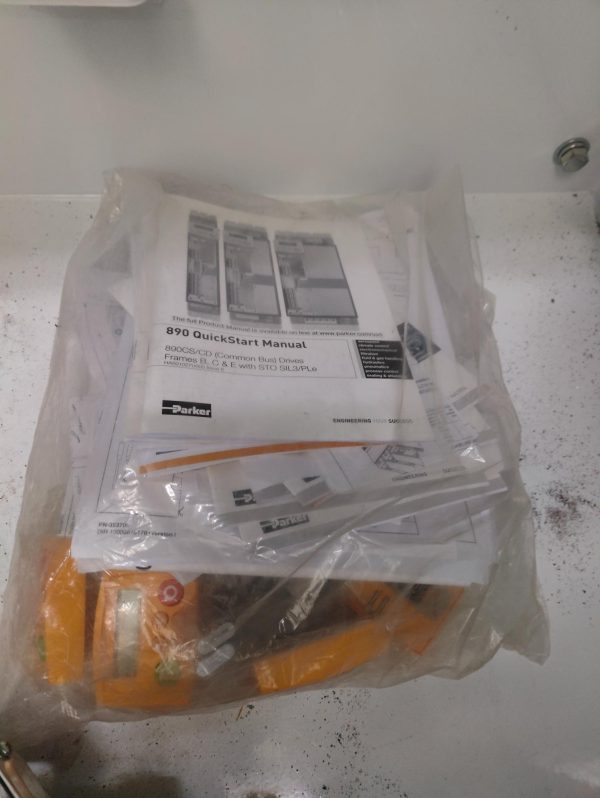

| Control | Parker Controller |

| Electrical Requirements | 480v – 3 ph |

| Note | New Replacement Cost $1.1 mil (+) |

FEATURES

| Razer Slitter | Shear Slitter |

Manufacturer Catalogue Information about Davis Standard Winding Unwinding Automation Roll Handling Machine :

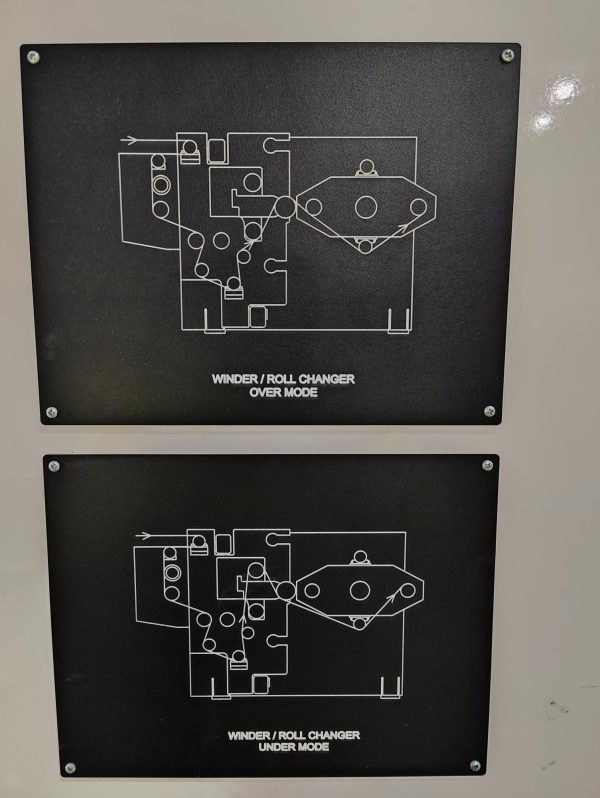

Winding and Unwinding Technology to Drive Productivity

Efficiency, value, performance – that’s the Davis-Standard solution in winding and unwinding. We have the industry’s largest selection of continuous winding and unwind systems and slitter rewinders.

We not only provide winding and unwinding technology, we provide solutions. Davis-Standard’s extensive line of equipment is supported by 50 years of first-hand experience in addressing the challenges of web handling, continuous splicing techniques and the pros and cons of inline slitting. Name the process – solution coating, extrusion coating, film, nonwoven and specialty applications – our winding and unwinding equipment is engineered for dependability, wound roll conformation and limited downtime.

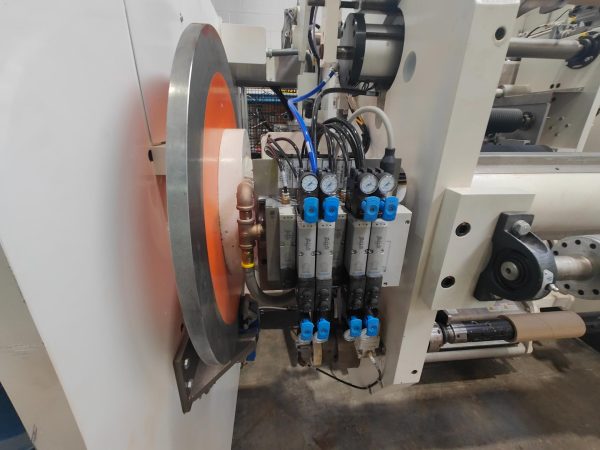

In addition to ATS, cantilevered, non-woven, H Beam and Surfastart technology, we supply roll handling and die control, transfer and splicing systems and no waste designs to boost your productivity and ROI.

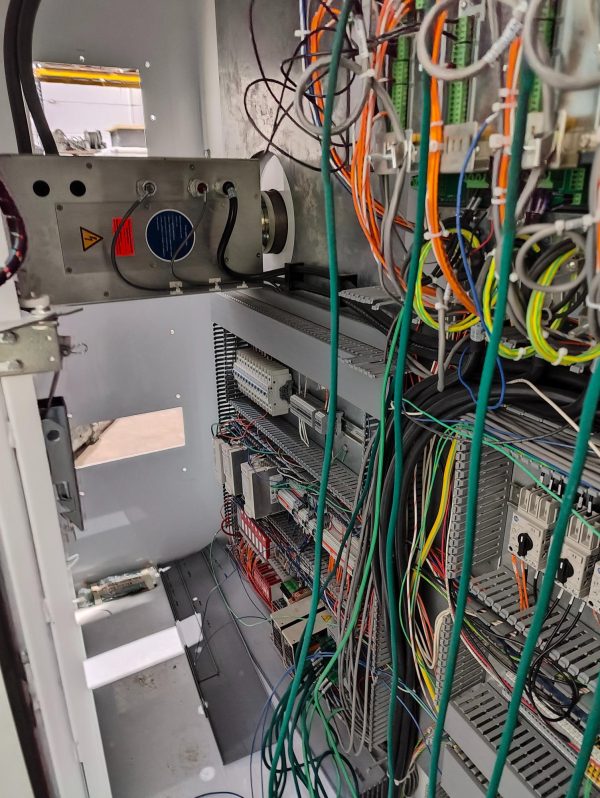

Automation Roll Handling

In the area of automation roll handling, Davis-Standard designs and builds pivot shaft systems, removable shaft systems, shaft pullers, and lift tables including the full integration of controls. Controls integration is also available for equipment supplied by a third party such as wrapping, conveying, and storage systems. Pivot shaft systems can be supplied with select machines. Both pivot shaft and removable shaft systems are available in fully-automatic or semi-automatic arrangements. Custom engineering is offered for new equipment as well as field retrofits.

Highlights of a typical pivot shaft system

45-second cycle times depending on application.

An unloading range of 30 to 90 degrees depending on facility space requirements.

Semi or automatic core loading with precision core positioning and core cutting options.

Doffing conveyors to automatically position the unloading roll diameter for a smooth transition, eliminating the possibility of shaft damage.

Highlights of typical removable shaft systems

Traversing lift table and pivot arm unloading systems for 80-second and greater than 80-second cycle times.

Semi or automatic core loading with precision core positioning and core cutting options.

Variable frequency driven mill duty shaft puller for smooth precision operation.

Lift tables with multiple options for different applications such as conveyor unloading, tilt tops, precision positioning for side-lay and offset wind applications.