Description

| Axis X | 120 mm |

|---|---|

| Axis Y | 120 mm |

| Axis Z | 200 mm |

| CNC | Siemens Sinumeric 840D |

| Max. part weight | 10 kg |

| Number of tool pockets | 60 |

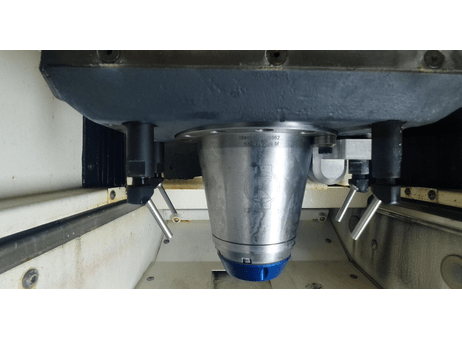

| Spindle taper | HSK-32 |

| Length x width x height | 4100.0 × 3700.0 × 2300.0 |

| Weight | 1800 kg |

| Worked hours | 937 hours |

| Hours under power | 2773 hours |

| State | good |

– Control: Siemens Sinumeric 840D with solutionline and easySONIC-Control

– Tool magazine: linear, chain

– Machined parts warehouse: Ph 2 | 120

– Number of axles: 5

– Machine on time: 2773h

– Spindle working time: 937h

– Travel in the X axis: 120 mm

– Travel in the Y axis: 120 mm

– Travel in the Z axis: 200 mm

– A axis: -10 ° to 120 °

– C axis: 360 °

– Main spindle: USB 40

– Maximum spindle speeds ULTRASONIC: 40,000 rpm

– Positioning accuracy in X / Y / Z: P10 µm

– X / Y / Z axis repeatability: P8 µm

– Feed rate range (X / Y / Z): up to 10,000 mm / min

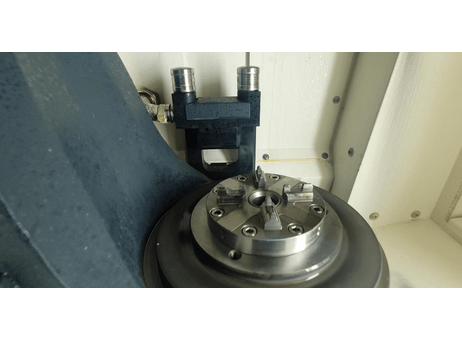

– NC work table with clamping surface: ø 190 mm

– Maximum table load: 10 kg

– Max.speed of rotary axes (A / B / C): 100 / – / 150rpm

– Axis positioning accuracy (A / B / C): ۯ

– Tool holder spindle: HSK-32 type

– Tool magazine: 60 items

– Store type: chain

– Max tool length with full capacity and maximum speed: 130mm

– Max tool diameter with full filling and maximum speed: 49mm

– Chip-to-chip replacement time: 15s

– measuring probe for the workpiece: DMG PP-400 Infrared

– measuring probe for tools: RS NC-4

– Coolant filtration equipment: KM 10

– occupied area: about 2 m2

– Machine dimensions with lamp (L / W / H): 1775/1530/2253 mm

– Space required with access to the service door (L / W / H): 4100/3700/2300 mm

– Weight: 1800 kg (without Ph 2 magazine)

– Total power consumption: 25 kVA

– Supply voltage: 400V (N / PE) / 50A

– Compressed air pressure: 6bar

– Average air consumption: 20 m3 / hour

Linear magazine for workpieces Ph2 | 120 SAUER

The most important advantages of integration with a linear warehouse

Integration of the Ultrasonic 10 with the PH 2 linear magazine | 120 SAUER ensures continuous machine operation and production automation.

– Unattended production in multi-shift work

– Compact, integrated linear magazine

– Mixed processing of various details possible

– Parallel loading and unloading of raw material and finished parts while the machine is being pressed

– Customer-specific pallet configuration possible

– The order management system allows you to easily manage your orders

Technical parameters of the PH2 linear warehouse | 120

– maximum weight for handling: 2 kg

– workpiece replacement time: less than 55s

– type of supported pallets: ITS 100 max 13 pcs, ITS 50 max 50 pcs, Finished part reservoir (FPR) 150 cs

– simple Dental configuration (ITS 100 / ITS 50 / FPR): 10 / – / 150

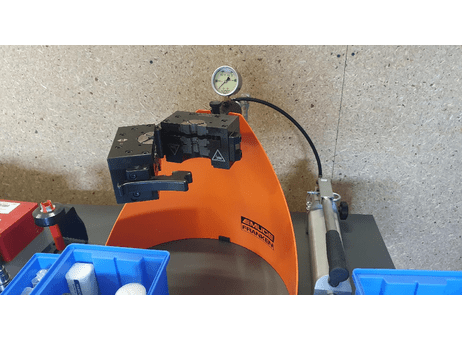

PowRgrip mounting system – Emuge Franken

Very quick change – on the PGR device the tool change takes place in 10 seconds – the collet is automatically pressed into the tool holder. Highly accurate concentricity guarantees reliable and reproducible tool life values and high surface quality ensure compliance with micron μ accuracy. The PGR system enables the clamping of very small tools – tungsten carbide and HSS shanks from a diameter of 0.2 mm. High clamping force and torque ensure extra safety. The special design of the handles to reduce vibrations and the long service life of the tool – greater than 20,000 clamping cycles.

– PGC manual clamping unit

– HSK-E32 PG06 x 80 collets – 3 pcs.

– HSK-E32 PG10 x 80 collet holders – 17pcs. (internal cooling)

DMG Mori Ultrasonic 10 SAUER CNC 5 Axes Machining Center